August 13, 2020

By Brianne Christopher

Category: Pubblications

International Conference on Robotics in Alpe-Adria Danube Region (06/2018)

Authors

Borboni, M. Serpelloni, M. Borghetti, C. Amici, F. Aggogeri, E. Sardini. R. Faglia Università degli Studi di Brescia

Fausti, M. Antonini, M. Mor Polibrixia srl

Abstract

Stroke patients are often affected by hemiparesis. In the rehabilitation of these patients the function of the hand is often neglected. Thus in this work we propose a robotic approach to the rehabilitation of the hand of a stroke patient in hospital and also at home. Some experimental results can be presented here especially for inpatients. Further experimental results on home-patients must be acquired through a telemedicine platform, designed for this application.

In book: New Trends in Medical and Service Robotics

Authors

- Ceresoli, F. Aggogeri, C. Amici, A. Borboni, R. Faglia, N. Pellegrini, M. Tiboni Università degli Studi di Brescia

- Antonini, D. Fausti, M. Mor, G. Petrogalli, A. Vertuan Polibrixia srl

Abstarct

This work proposes a new device for lower and upper limb rehabilitation. The device is portable and modular and can be adopted to realize different system configurations and to perform different exercises. A design description and an analysis are shown, a working prototype is under construction and tests on humans are planned.

International Conference on Mechatronics Technology (ICMT) (10-2019)

C. Amici, M. Ghidoni , F. Ceresoli, F. Ragni, M. Tiboni University of Brescia, Brescia, Italy

P. Gaffurini, L. Bissolotti Domus Salutis Rehabilitation Clinic, Teresa Camplani Foundation

M. Mor, D. Fausti, M. Antonini Polibrixia s.r.l., Brescia, Italy

Abstract:

Objective: Robotic devices are commonly used in rehabilitation as support to physiotherapists in their daily rehabilitation activities, since they can monitor and quantify the subject’s performance and deliver feedback, as well as supply physical therapy. This work aims at performing a preliminary validation of an innovative device, developed within the SIMeRiON funded project, and identifying the optimal experimental setup for the clinical trials, through the analysis of the characteristics of a planar reaching movement impressed to the upper limb of the subject in a sequence of repetitions. Methods: A male healthy subject (26 years old) has been recruited, and asked to perform an imposed reaching movement with his left arm, during three consecutive sessions. The subject was instrumented with two triaxial accelerometers, placed in two possible configurations, and eight passive optical markers evaluated with a two fixed cameras optoelectronic system. To identify and compare different motion cycles, the collected data have been analyzed in MATLAB and R environment. Results: Data emphasize a high repeatability of the imposed movement, especially at human-machine interface, and suggest that accelerometers data could be integrated with different sensors (e.g. sEMG sensors).

International Journal of Materials and Product Technology 60(1):18 (01-2020)

Abstract

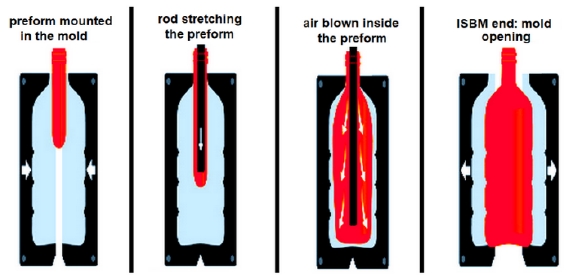

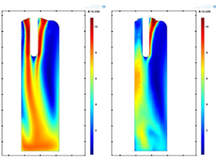

Polyethylene terephthalate (PET) is a widely used polymer in the production of bottles by injection stretch blow moulding (ISBM). In this work, we present a characterisation method to identify material properties directly from a preform, considering temperature and stress-relaxation effects related to its viscoelastic response. A customised oven and gripping system were designed to perform uniaxial tests in a proper temperature range on tubular specimens obtained from preforms. A visco-hyperelastic model is then proposed: a Marlow-type strain energy function coupled with a Prony series and William-Landel-Ferry equation to include time and temperature dependency. Finally, a case study of ISBM process is implemented in a finite element code considering this constitutive model. Strain maps and predicted thickness of the bottle wall were evaluated as process quality indicators. Simulation results showed good agreement with measurements on the real processed bottle, confirming the usefulness of the approach for product or process parameters optimisation.

M. Antonini [1], D. Fausti [1], M. Mor [1],

[1] PoliBrixia s.r.l., Brescia, Italy

In this paper, the “Morton Effect” is analyzed. This phenomenon is a particular kind of rotor instability due to non-uniform journal bearing heating. In this paper, an overview of the previous works has been done. After this preliminary study, a specific approach suggested by literature has been chosen and analyzed. A thermal model, a rotor dynamic model and a stability criterion were implemented with COMSOL®.

M. Mor[1], C. Seneci[1], V. Zacché[1], C. Remino[1], G. Petrogalli[1], D. Fausti[1],

[1]Polibrixia, Brescia, Italy

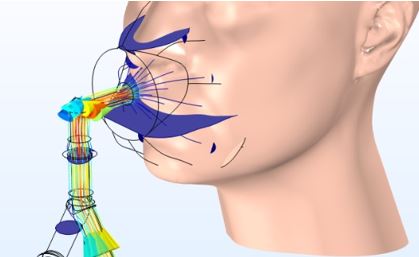

This paper presents the study and design of a new generation oven for PET blow-molding machines. The design faced several technical challenges such as: the temperature distribution in the critical areas, the sharp curvature radius, the high PET thermal inertia and the presence of boundary elements, which affected the overall performances. The work included an analysis of the preform material and geometric influence on the heating and transformation process, followed by the definition of the model to implement in a simulation. Finally a series of simulations aimed to simulate the infra red heating system and the convective cooling system, necessary to control the heating process, achieving the ideal temperature distribution, more efficiency, energy saving and higher modularity.

Research activity carried out for Salei-SIL Lumezzane (Brescia), in collaboration with the Department of Mechanical and Industrial Engineering of the University of Brescia.

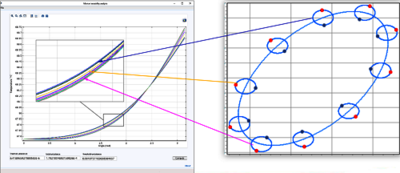

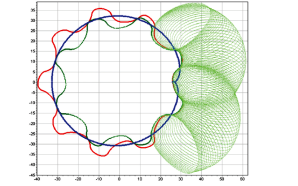

The first objective of the work is to identify a general mathematical methodology for the synthesis of the profile of the gerotor pump. The classic approach allows to generate profiles from typical circular generating curves; We want to extend the methodology to generally complex geometric shapes describable by Bezier curves.

The generation of the procedure brings with it a greater flexibility in the form of the obtained profiles and therefore a greater freedom of choice of the profile that best respects the specific needs to which the pump will have to face. We want to propose an automatic search for the best solution.

The features for pumps are the following:

-Low noise

– Wear and tear

-High Efficiencies

– Respect to cylinder displacements and maximum dimensions.

We intend to propose a methodology of excellent.