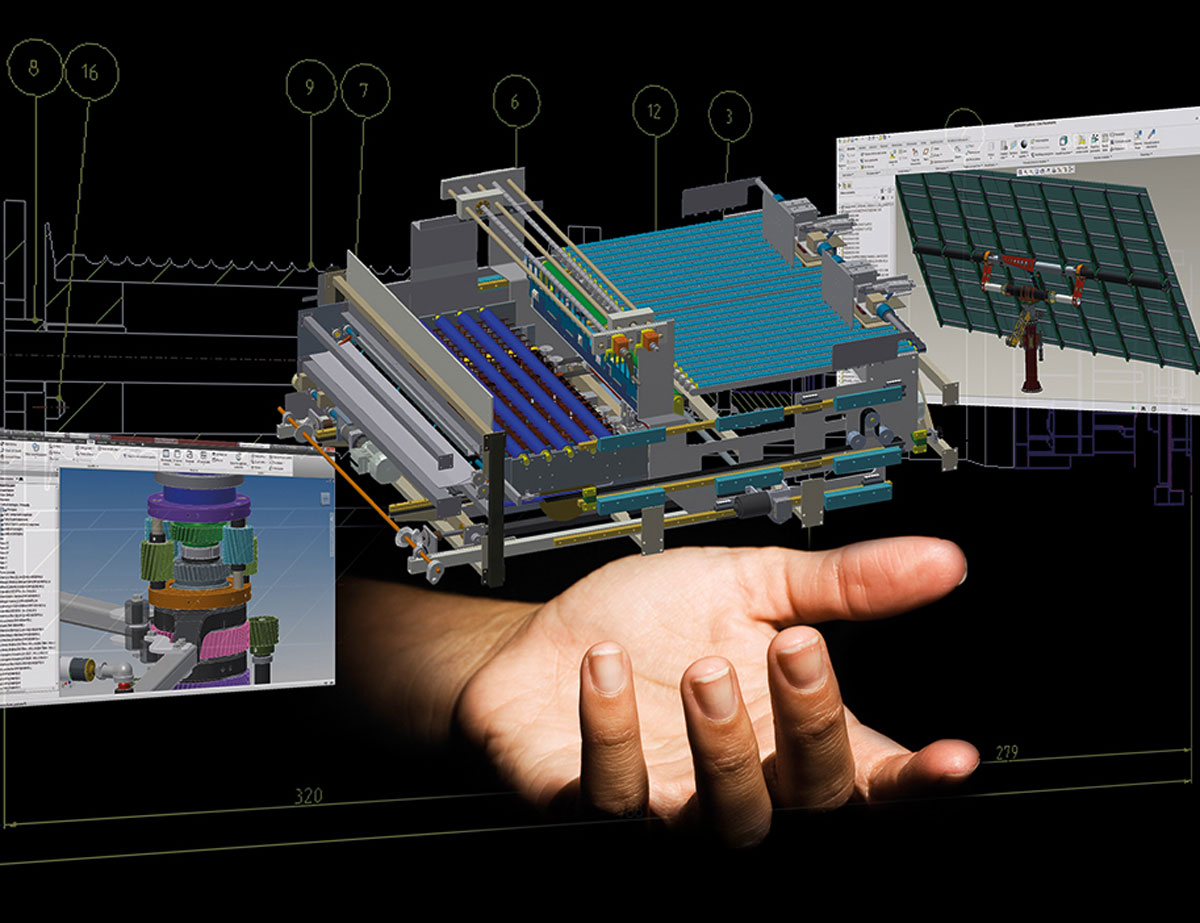

MECHANICAL DESIGN

Build your new machines and prototypes tailor-made

A constant and complete engineering support. From the sharing of the objectives to the delivery of the executive project, Polibrixia is able to realize analysis and synthesis of the technology and the mechanisms best suited to the specific needs of the customer in synergy with Its processes, times and methodologies. Competence and flexibility in the use of the best CAD technologies to meet the most common company standards.

From the sizing to the configuration of the components, to the materials and their treatments, to the kineto-dynamic study.

One goal: to create effective solutions.

A targeted design is able to:

• Solve problematic issues and errors;

• Innovate by optimizing processes and products;

• Achieve higher standards of productivity and security;

• Improve competitiveness and overall efficiency.

From the sizing to the configuration of the components, to the materials and their treatments, to the kineto-dynamic study.

One goal: to create effective solutions.

A targeted design is able to:

• Solve problematic issues and errors;

• Innovate by optimizing processes and products;

• Achieve higher standards of productivity and security;

• Improve competitiveness and overall efficiency.

INDUSTRIAL AUTOMATION

Simplify the human work component and automate your production systems

Mechanical. Electronics. Computer science. Three distinct specialized areas that in Polibrixia interact constantly with each other operating according to a systemic logic, a synergistic fusion that takes the name of Mechatronics.

From the concept, to the development of the project, to the finalization of the prototype, Polibrixia elaborates a wide-ranging overview in which the physical variables of the products and industrial processes integrate with the automation technologies to offer a new Machine concept.

The advantages of an integrated design approach are many and allow to develop new and more effective solutions capable of:

• Reduce the time and cost of increasing production;

• Solve criticality and errors;

• Improve the quality of the products;

• Gain more efficiency and productive flexibility by optimizing processes.

From the concept, to the development of the project, to the finalization of the prototype, Polibrixia elaborates a wide-ranging overview in which the physical variables of the products and industrial processes integrate with the automation technologies to offer a new Machine concept.

The advantages of an integrated design approach are many and allow to develop new and more effective solutions capable of:

• Reduce the time and cost of increasing production;

• Solve criticality and errors;

• Improve the quality of the products;

• Gain more efficiency and productive flexibility by optimizing processes.

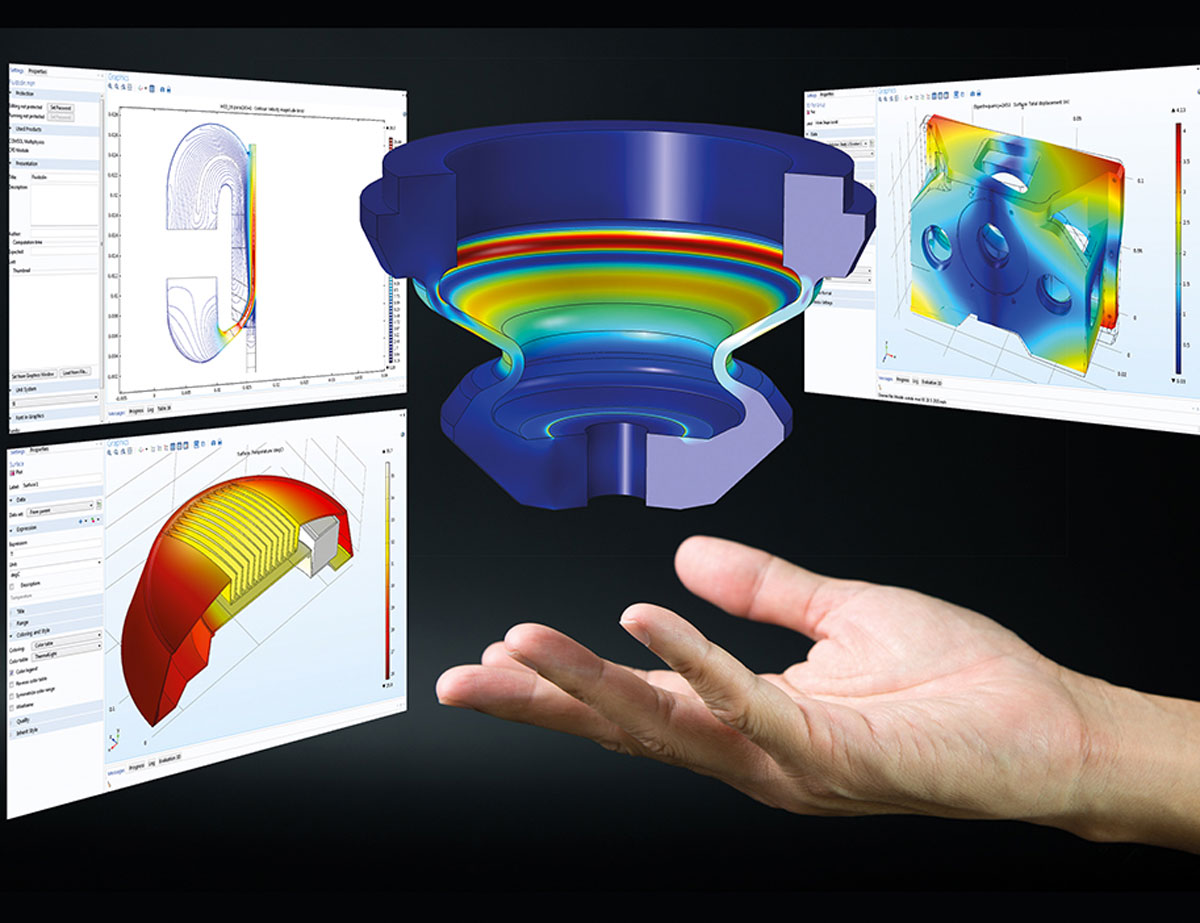

MULTIPHYSICS FEM SIMULATION

Innovate and optimize your products and production processes

Polibrixia is the first company operating in the area central-north Italy, recognized and certified COMSOL, able to offer one of the most advanced services for the virtual simulation of the physical dynamics that intervene on your product and/or production process.

Polybrixia is able to perform analysis:

• Structural (linear and non models, modal analysis, frequency response)

• Thermal

• CFD

• Multiphysics

The advantages of a virtual simulation are multiple:

• Reduce development time and cost and set up the prototype;

• Test the structural behaviour of components or assemblies;

• Optimise production processes;

• Anticipate and resolve in advance potential criticalities before they represent an economic and image damage to the company.

Polybrixia is able to perform analysis:

• Structural (linear and non models, modal analysis, frequency response)

• Thermal

• CFD

• Multiphysics

The advantages of a virtual simulation are multiple:

• Reduce development time and cost and set up the prototype;

• Test the structural behaviour of components or assemblies;

• Optimise production processes;

• Anticipate and resolve in advance potential criticalities before they represent an economic and image damage to the company.

SCIENTIFIC AND INDUSTRIAL SOFTWARE DEVELOPMENT.

Increase your productivity. Streamline your processes reduce your task management time.

A constant and highly specialized computer support. Strongly connected to the research activities, and even more to the industrial automation and mechanical design, Polibrixia includes within it also a specific division dedicated both to the computerization of systems of analysis and calculation and to the management of machines and industrial processes.

Polibrixia is able to develop software:

• Process-user interface and machine control;

• Scientific, using the most effective numerical calculation methods;

• For the custom-tailored kineto-dynamic simulation on

specific needs;

• Ad-hoc, treatment and signal analysis.

In line with modern technologies, Polibrixia also develops on IOS and Android platforms.

The potential of an integrated software development allows your company to:

• Shaping the physical phenomena of interest in the best way

• Optimize phases and processes based on specific objective functions

• Collect and process data and information

• Constantly control and manage activities even remotely

• Improve the overall productivity of the plants. specific needs;

• Ad-hoc, treatment and signal analysis.

In line with modern technologies, Polibrixia also develops on IOS and Android platforms.

The potential of an integrated software development allows your company to:

• Shaping the physical phenomena of interest in the best way

• Optimize phases and processes based on specific objective functions

• Collect and process data and information

• Constantly control and manage activities even remotely

• Improve the overall productivity of the plants.

Polibrixia is able to develop software:

• Process-user interface and machine control;

• Scientific, using the most effective numerical calculation methods;

• For the custom-tailored kineto-dynamic simulation on

specific needs;

• Ad-hoc, treatment and signal analysis.

In line with modern technologies, Polibrixia also develops on IOS and Android platforms.

The potential of an integrated software development allows your company to:

• Shaping the physical phenomena of interest in the best way

• Optimize phases and processes based on specific objective functions

• Collect and process data and information

• Constantly control and manage activities even remotely

• Improve the overall productivity of the plants. specific needs;

• Ad-hoc, treatment and signal analysis.

In line with modern technologies, Polibrixia also develops on IOS and Android platforms.

The potential of an integrated software development allows your company to:

• Shaping the physical phenomena of interest in the best way

• Optimize phases and processes based on specific objective functions

• Collect and process data and information

• Constantly control and manage activities even remotely

• Improve the overall productivity of the plants.

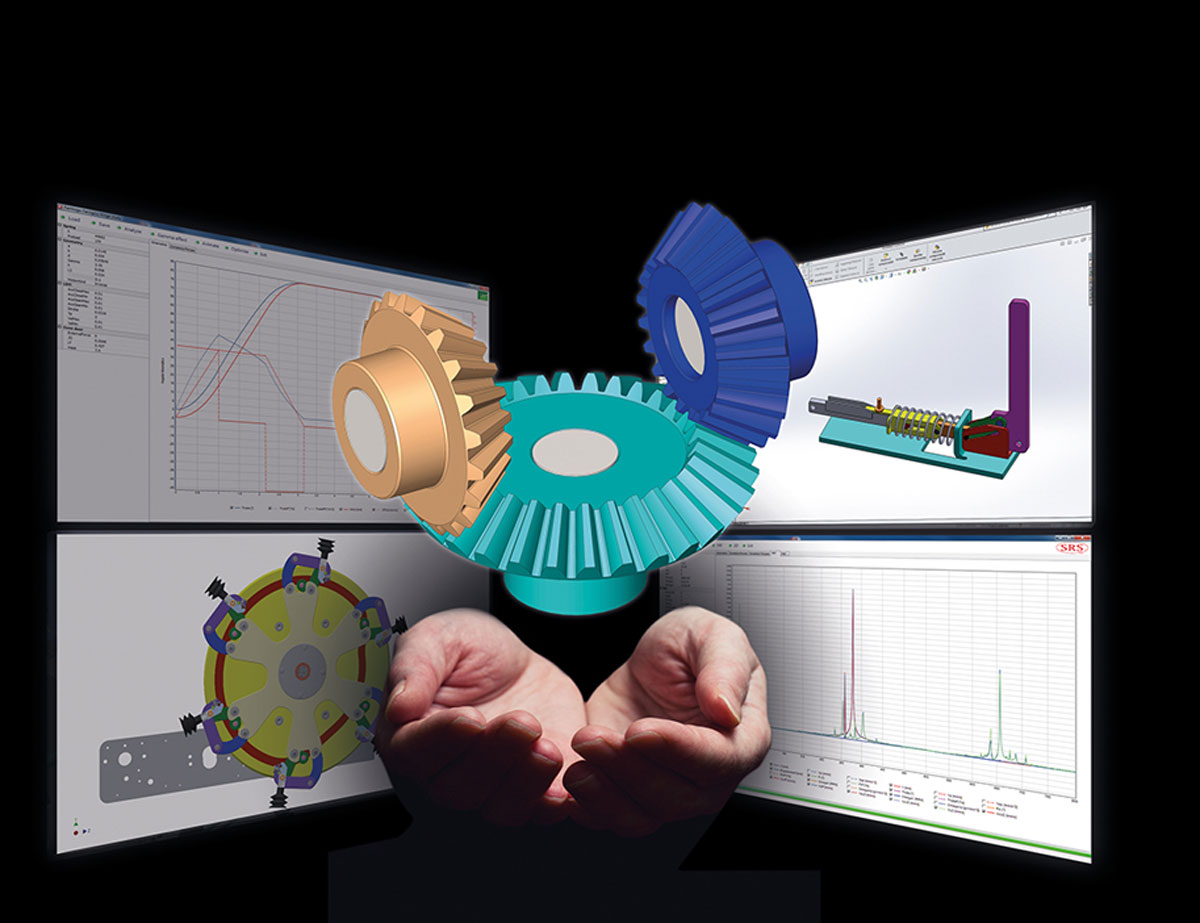

KINETO-DYNAMICS SIMULATIONS MULTIBODY

Analyze and better define the behavior of your systems in motion

Multibody analysis allows to simulate the kinematic and dynamic behavior of mechanical assemblies composed by parts in reciprocal motion, to plan the optimal trajectories of work, to optimize speed and accelerations and to evaluate the forces exchanged between the Bodies.

Polibrixia performs this type of analysis using specialized software, but also developed ad- hoc calculation procedures:

Polybrix is able to carry out:

• Analysis and synthesis mechanisms;

• Profiling of CAM systems;

• Optimize motor laws;

• Study the trajectories of work.

With the kineto-dynamic study permitts us to:

• Increase the performance of your machines;

• speed up your processes;

Polibrixia performs this type of analysis using specialized software, but also developed ad- hoc calculation procedures:

Polybrix is able to carry out:

• Analysis and synthesis mechanisms;

• Profiling of CAM systems;

• Optimize motor laws;

• Study the trajectories of work.

With the kineto-dynamic study permitts us to:

• Increase the performance of your machines;

• speed up your processes;